Material Regeneration

Plasmas work faster to achieve the same outcome as conventional heating

Regenerates sorbents in minutes

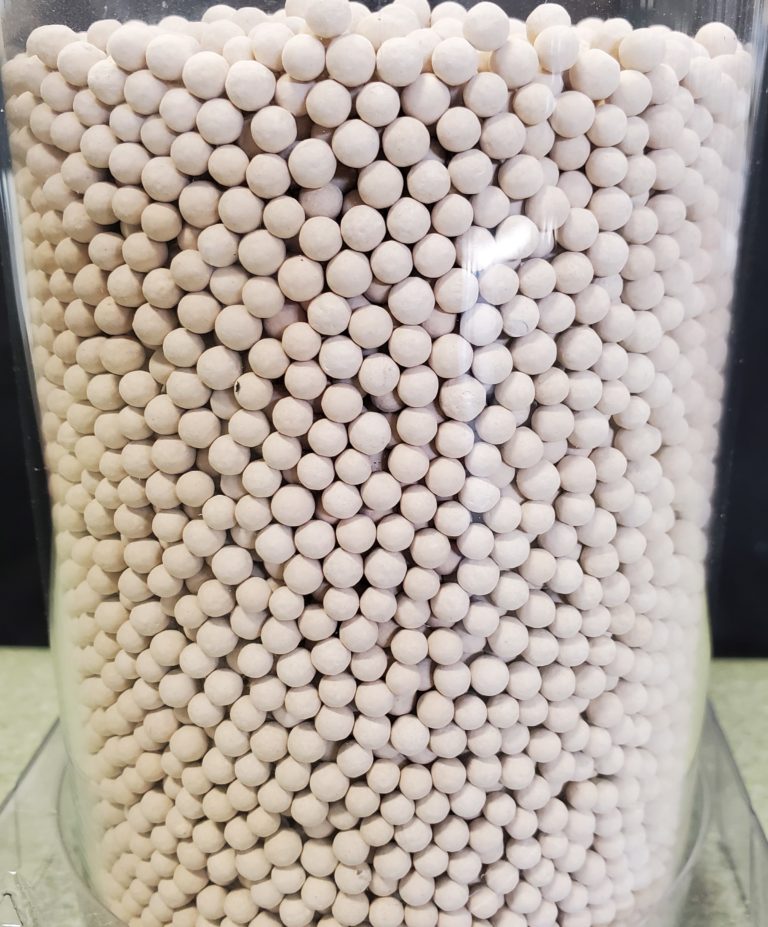

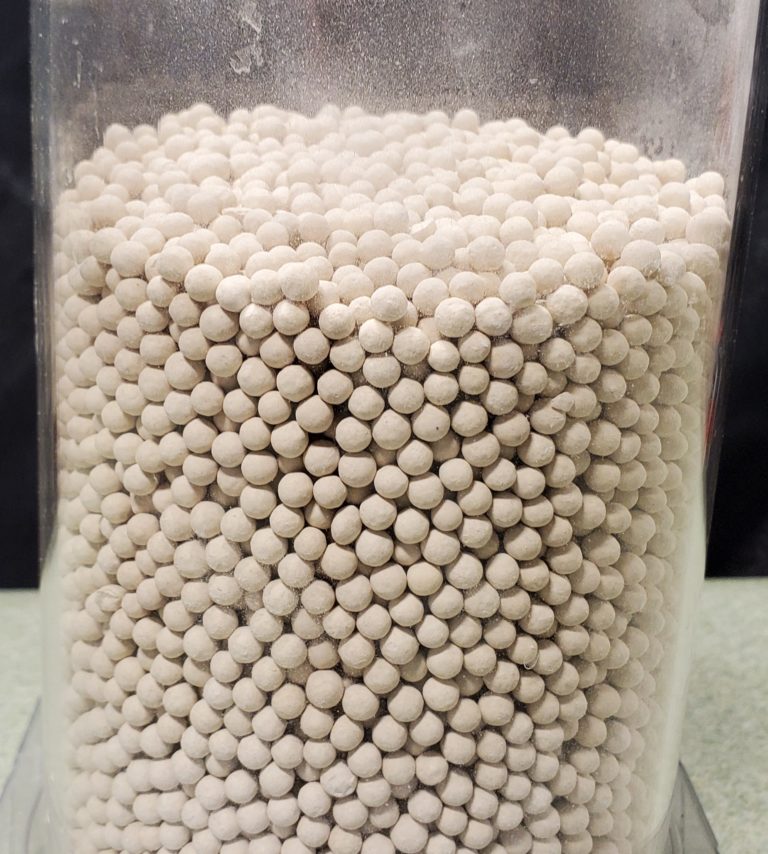

For manufacturing, MagPlasma is applying plasmas to replace conventional heating in processes that activate surfaces and regenerate adsorption media.

Plasma processing replaces thermal processes enabling:

Faster Processing Lower Energy Consumption Tailor Surface Properties

For sorbent regeneration, the MagPlasma process can be used to replace thermal heating in temperature swing adsorption processes (TSA).

How it Works: Plasma Swing Material Regeneration

MagPlasma is applying plasmas to replace conventional heating in a variety of industrial processes. Using plasmas to replace conventional heating is like microwaving food vs. using a conventional oven. Plasmas work faster, use less energy, and often have lower capital equipment costs than conventional heating systems. that activate surfaces and regenerate adsorption media.

Conventional state-of-the-art chemical species adsorption and material regeneration is performed by temperature swing adsorption/desorption (TSA) and/or combined with pressure swing adsorption/desorption (PSA). In both TSA and PSA, chemical species are adsorbed onto a material surface or absorbed into the material at one temperature or pressure and then desorbed by increasing either the temperature or pressure (or both) of the material. MagPlasma’s new Plasma Swing Adsorption works like TSA but uses plasma energy to desorb chemical species. PLSA is faster than conventional TSA and does not use heat, so it causes less material degradation over repeated use.

In TSA, the temperature of the unit containing the sorbent material is lowered to increase chemical species adsorption onto/into a material. To regenerate the material (i.e., cycle it for reuse), the temperature is increased which then causes the chemical species to desorb from the material and opens the material for a new cycle of adsorption.

In PSA, the pressure of the unit containing the sorbent material is lowered to increase chemical species adsorption onto/into a material. To regenerate the material (i.e., cycle it for reuse), the pressure is increased which then causes the chemical species to desorb from the material and opens the material for a new cycle of adsorption.

PLSA operates like TSA except that material regeneration does not require a change in temperature. Instead, desorption of chemicals is caused by plasma energy versus thermal energy. To regenerate the material (i.e., cycle it for reuse), the plasma is turned on for a few minutes to desorb chemicals species from the surface for a new cycle of adsorption. Since the temperature of the material is not changed, the material is immediately ready to begin a new adsorption cycle.

our solution

Plasma field regeneration acts similarly to TSA but uses plasma energy to replace thermal energy. In plasma field regeneration, the temperature of the material is not changed. The chemical species adsorbs onto the surface or is absorbed into the material at a set temperature which is independent of the process. To regenerate the material for reuse, a plasma field is formed around the material. The plasma field imparts energy into the adsorbed/absorbed chemical species which causes it to desorb from the material and open the material for reuse.

- Plasma enables faster processing

- Lower energy consumption

- Ability to tailor surface properties