Disinfection for your Highest Value Equipment

Disinfect sensitive materials and electronics in a dry, ambient temperature process-no harsh chemicals - no steam.

No harsh chemicals No steam Safe for sensitive electronics No light limitations

Protection at the source. Disinfect sensitive materials and electronics in a dry, ambient temperature process-no harsh chemicals - no steam.

How it works

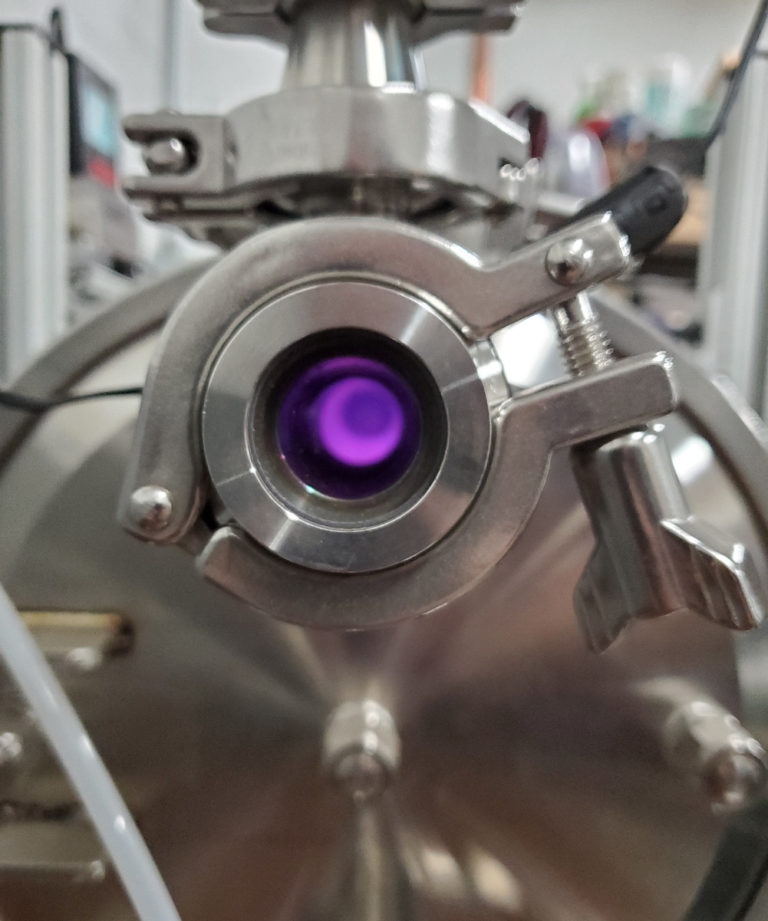

Plasma systems disinfect by high energy transfer from highly charged particles (“cloud” of ions and electrons), so they can penetrate around and into surfaces.

Conventional equipment disinfection processes, especially those used in healthcare facilities, use harsh liquid disinfectants or high temperature/wet processes such as steam autoclaving or plasmas combined with chemical additives such as hydrogen peroxide. These processes are not viable for use with sensitive electronic hardware. New disinfection technologies are emerging that use UV light; however, these systems have limitations that affect their employment. Specifically, UV light systems can only disinfect surfaces where the light touches (i.e., does not disinfect areas shaded due to surface cracks/crevices or complex structures).

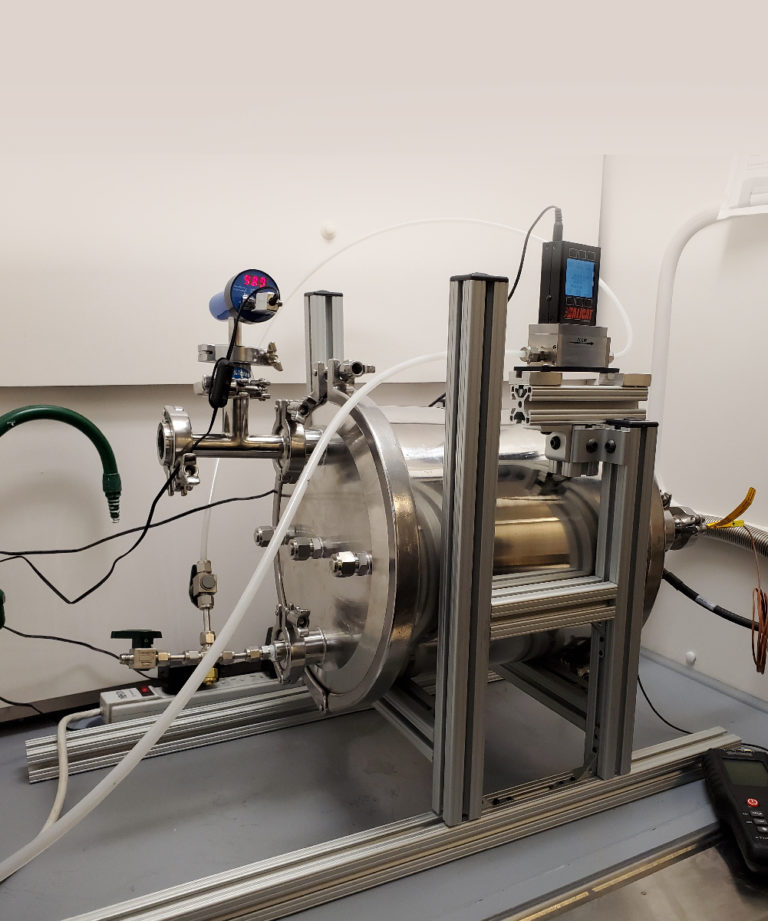

Plasma Autoclave

Our plasma autoclave disinfects items that cannot, or should not, be processed in conventional high pressure/steam autoclaves. The plasma autoclave does not use “wet” additives such as steam or aerosol disinfectants (e.g. hydrogen peroxide). As a fast, point-of-use system, the plasma autoclave can also be used by workers to quickly disinfect PPE, or other equipment, throughout their duty day. This eliminates the need for additional staff to collect, disinfect, and return equipment to users.

- Actively kill >99.99% viruses in minutes

- Disinfects in crevices and cracks

- Runs on 110-volt AC

- Operates at ambient temperature

- Does not use OSHA regulated chemicals

- Does not use high pressure or steam